Horizontal Balers

We sell and lease hire a range of Horizontal Balers to suit every business.

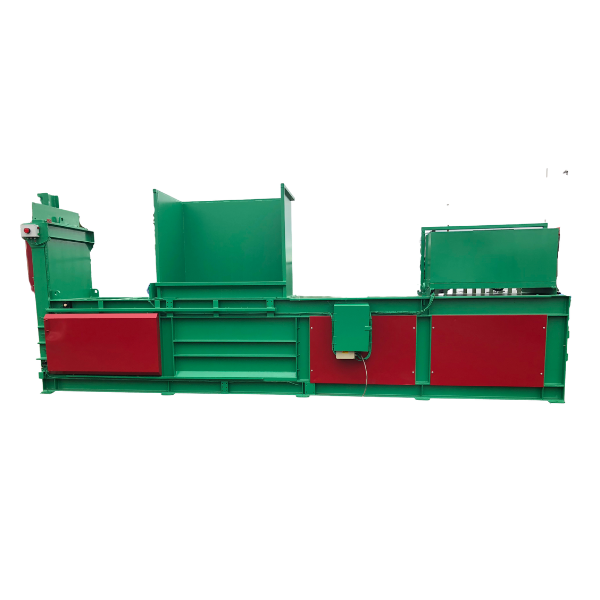

Semi-Automatic Horizontal Baler (500/600 kg Bales)

Horizontal Balers

Semi-Automatic Horizontal Baler (500/600 kg Bales) Semi-automatic horizontal balers are the excellent solution for distribution and logistic centers, retail stores,…

Fully Automatic Horizontal Baler (500/600 kg Bales)

Horizontal Balers

Fully Automatic Horizontal Baler (500/600 kg Bales) Fully automatic horizontal balers are a versatile choice for waste handling facilities, retail…

Free Delivery Available

We offer nationwide delivery, installation and training as standard

Servicing Included

As part of your purchase will include free servicing at regular intervals

UKWR Warranty

All of machines are covered by our UKWR warranty scheme

Generate Rebates

We offer competitive cash rebates on your recyclable goods

Horizontal Balers Frequently asked Questions

What is a Horizontal Baler?

Horizontal balers are industrial machines used for compacting and bundling waste materials such as paper, cardboard, plastic, and metal into dense, uniform bales for efficient storage and transport. They are typically larger and more powerful than their vertical counterparts, making them ideal for businesses that generate a substantial volume of waste or recyclable materials. Their automation capabilities reduce labor costs, and the consistency in bale size and weight makes waste management more efficient.

What is the difference between Vertical and Horizontal Balers?

Vertical and horizontal balers are both types of waste compacting machines, but they differ significantly in their operation, capacity, and application. Vertical balers operate in an up-and-down motion, where waste materials are loaded from the top and compacted downwards into bales. They are generally smaller and suitable for businesses that generate a moderate amount of waste or recyclable materials. Horizontal balers operate in a side-to-side manner, where materials are loaded from one end and compacted into bales that are ejected from the other. They are larger, more powerful, and designed to handle higher volumes of waste, making them ideal for businesses with substantial waste generation.

Which Horizontal Baler is right for my business?

Determining the right horizontal baler for your business involves a careful consideration of several factors. Firstly, assess the volume and type of waste your business produces; larger volumes or bulkier materials may require a high-capacity, robust baler. Secondly, consider the available space in your facility; horizontal balers require more room than vertical ones, so ensure you have enough space for operation and maintenance. Thirdly, review your budget and consider both initial purchase costs and ongoing operational expenses. Lastly, automation can be a vital factor if your objective is to save on labor costs. It’s often beneficial to consult with a waste management professional or baler supplier to ensure you choose a baler that aligns with your specific needs.

What types of material can I bale?

Horizontal balers are versatile machines capable of baling a wide range of materials. These include:

- Paper: This includes office paper, newspaper, magazines, and cardboard.

- Plastic: This covers a variety of plastics such as PET bottles, plastic film, and rigid plastics.

- Textiles: Used clothes, rags, and other textile waste can be baled for recycling or disposal.

- Metals: Light metals such as aluminium cans or foil.

- Agricultural waste: This includes hay, straw, and silage, among other types of agricultural waste.

- Industrial waste: This could include anything from packaging materials to non-toxic industrial byproducts.

Remember that the specific capabilities of a horizontal baler can vary depending on its design and the installed features, so it’s essential to consult with a supplier or manufacturer to ensure the baler you select is suitable for the materials you need to process.