Plastic Balers

Plastic Balers, designed to compact large volumes of waste plastic into manageable bales, saving you time, space, and disposal costs.

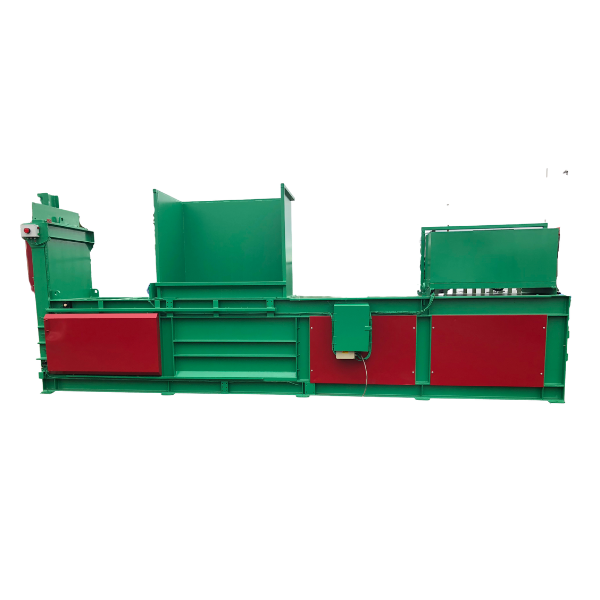

Semi-Automatic Horizontal Baler (500/600 kg Bales)

Horizontal Balers

Semi-Automatic Horizontal Baler (500/600 kg Bales) Semi-automatic horizontal balers are the excellent solution for distribution and logistic centers, retail stores,…

UK 75 Vertical Baler

Vertical Balers

UK75 Series Vertical 75Kg Baler are ideal for small convenience stores, petrol stations, factories, manufacturing businesses, distribution/wholesale warehouses and more.

UK250 Series 250Kg Twin Chamber Baler

Cardboard Balers

UK250 Series 250Kg Twin Chamber Baler Twin chamber balers are hand fed machines, ideally suited for baling materials such as…

UK300 Series Vertical 300Kg Baler

Vertical Balers

UK300 Series Vertical 300Kg Baler 300Kg vertical balers are hand fed machines, ideally suited for baling materials such as cardboard,…

UK600 Series Vertical Mill Size Baler

Vertical Balers

UK600 Series Vertical Mill Size Baler Mill size vertical balers are hand fed machines, ideally suited for baling materials such…

Free Delivery Available

We offer nationwide delivery, installation and training as standard

Servicing Included

As part of your purchase will include free servicing at regular intervals

UKWR Warranty

All of machines are covered by our UKWR warranty scheme

Generate Rebates

We offer competitive cash rebates on your recyclable goods

Plastic Balers Frequently asked Questions

What is a Plastic Baler?

A plastic baler is a specialised machine designed to compress and bundle various types of plastic waste into compact, uniform bales. Plastic balers are commonly used in industries that produce large amounts of plastic waste, including manufacturing, retail, and recycling centres. By facilitating efficient waste management, they not only help in reducing disposal costs but also contribute to environmental sustainability by preparing plastic waste for recycling.

What maintenance is required for Plastic Balers?

Like any industrial machinery, plastic balers require regular maintenance to ensure optimal performance and longevity. This usually involves routine inspections to detect wear and tear, particularly in high-stress areas like the hydraulic system and the pressing chamber. Regular cleaning is essential to prevent buildup of plastic residue that could lead to jams or mechanical issues. The baler’s hydraulic fluid levels should be checked and replenished as necessary, and hydraulic lines should be inspected for leaks. Additionally, moving parts may require lubrication to minimise friction and wear. Safety systems, such as emergency stop mechanisms, should also be tested regularly to ensure they are functioning correctly. Always refer to the manufacturer’s manual for specific maintenance guidelines and schedules for your particular baler model.

How does a Plastic Baler work?

A plastic baler operates by compressing plastic waste into compact bales. The process begins by loading the plastic into the machine. Then, a hydraulic or mechanical press compacts the material significantly. After compression, the compacted plastic is secured into a bale using wires, straps, or netting. Finally, the bale is ejected from the machine, ready for easy handling, storage, or transport.

What are the different types of Balers?

Selecting a baler involves considering the nature and volume of waste material, space constraints, and budget. Baler manufacturers offer diverse models tailored to various customer requirements, with some focusing on equipment for specific sectors, ranging from food waste to metal scrap. Understanding the purpose and intended use of the baler is crucial to making the right choice.