Cardboard Balers

Cardboard Balers, designed to compact large volumes of waste cardboard into manageable bales, saving you time, space, and disposal costs.

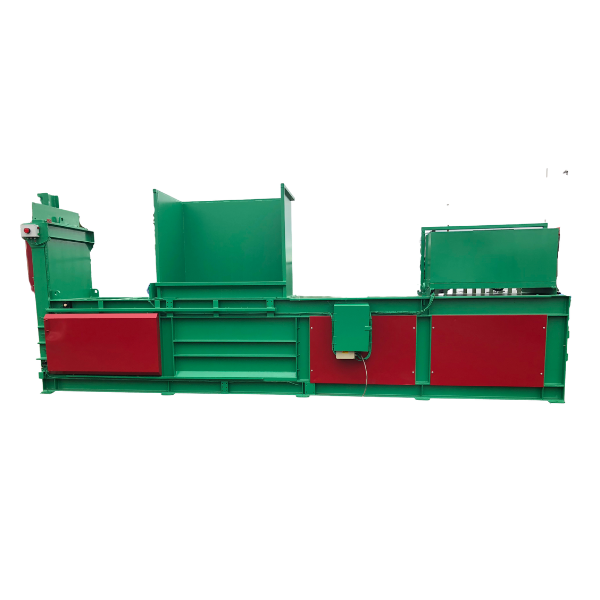

Semi-Automatic Horizontal Baler (500/600 kg Bales)

Horizontal Balers

Semi-Automatic Horizontal Baler (500/600 kg Bales) Semi-automatic horizontal balers are the excellent solution for distribution and logistic centers, retail stores,…

UK 75 Vertical Baler

Vertical Balers

UK75 Series Vertical 75Kg Baler are ideal for small convenience stores, petrol stations, factories, manufacturing businesses, distribution/wholesale warehouses and more.

UK250 Series 250Kg Twin Chamber Baler

Cardboard Balers

UK250 Series 250Kg Twin Chamber Baler Twin chamber balers are hand fed machines, ideally suited for baling materials such as…

UK300 Series Vertical 300Kg Baler

Vertical Balers

UK300 Series Vertical 300Kg Baler 300Kg vertical balers are hand fed machines, ideally suited for baling materials such as cardboard,…

UK600 Series Vertical Mill Size Baler

Vertical Balers

UK600 Series Vertical Mill Size Baler Mill size vertical balers are hand fed machines, ideally suited for baling materials such…

Fully Automatic Horizontal Baler (500/600 kg Bales)

Horizontal Balers

Fully Automatic Horizontal Baler (500/600 kg Bales) Fully automatic horizontal balers are a versatile choice for waste handling facilities, retail…

Free Delivery Available

We offer nationwide delivery, installation and training as standard

Servicing Included

As part of your purchase will include free servicing at regular intervals

UKWR Warranty

All of machines are covered by our UKWR warranty scheme

Generate Rebates

We offer competitive cash rebates on your recyclable goods

Turn this…

To this!

Cardboard Balers Frequently asked Questions

What is a Cardboard Baler?

A cardboard baler is a machine that is specifically designed to compress cardboard waste into compact, manageable bales for easier handling, storage, and transportation. Cardboard balers are commonly used in businesses that generate a significant amount of cardboard waste, such as supermarkets, warehouses, recycling centres, and manufacturing plants. They help in waste management. and reduce disposal costs.

How does a Cardboard Baler work?

A cardboard baler operates by compacting loose cardboard into dense bales. Cardboard is loaded into the baler, then a hydraulic or mechanical press compresses it. The compacted cardboard is secured with wires or straps, forming a bale. The bale is then ejected, ready for easy storage, transport, or sale to recycling facilities.

What type of cardboard should be placed in a baler?

A baler can accept various types of cardboard, making it a versatile piece of equipment for waste management. This includes:

- Corrugated Cardboard (OCC): This is the most common type of cardboard and is widely used in packaging and shipping boxes. It’s ideal for baling due to its durability and recyclability.

- Cardboard Cartons: These include food and drink packaging, such as cereal boxes and milk cartons.

- Paperboard or Chipboard: This thinner, less durable type of cardboard, often used in packaging consumer goods, can also be baled.

Before placing cardboard in a baler, ensure it’s free of contaminants like food waste, plastic wrap, or metal. Cardboard should also be flattened to improve the efficiency of the baling process. Always consult the baler’s manual or manufacturer to confirm the types of materials suitable for your specific model.